Technical Note: Direct Operating Costs

On the Cost of One Flight Hour

FLIGHT-X can calculate the Direct Operating Costs (DOC) of the airplane, on the basis of over 40+ cost parameters, which are established in a configuration file that can be found in the airplane model sub-folder. The parameters that are considered in the DOC analysis include:

Currency, aircraft cost, current fuel price, fuel price inflation, fuel shock price and corresponding fiscal year, insurance costs, spare parts on category I (airframe, landing gear, tyres), spare parts on category II (engines, APU, lubricants), spare parts on category III (avionics, systems, modernisation, refurbishment); aircraft life-time, depreciation, financing, interest rates, mortgage life-time, crew costs on category I (pilots and co-pilots), crew costs on category II (flight attendants), off-station costs (overnight out of position); labour rates on category I (power plant), labour rates on category II (in house), labour rates on category III (outsourced); flight services costs, ground services costs, average stage length. FLIGHT-X estimates the following:

- Number of pilots required for operating the aircraft year round.

- Number of flight attendants required for operating the aircraft year round.

- Number of cycles and airplane utilisation.

- Off-station crew nights.

- Fuel burn per cycle.

- Block time per cycle.

- Cost per available seat mile (CASM).

- DOC/n-mile flown.

- Ticket price required to break even, with and without commercial cargo.

FLIGHT-X accounts for the following externalities:

- Increase in fuel consumption due to deterioration and engine wash.

- Any other eventuality, which can be included in a mission scenario.

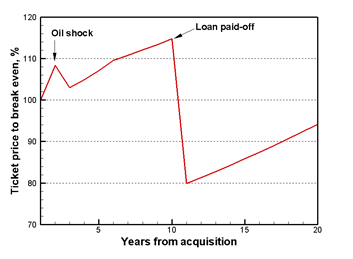

The figure below shows the estimated ticket price required to break even for a hypothetic aircraft costing 27 million dollars, acquired with internal financing (20%) and external financing (80%) over a period of 10 years, assuming that the aircraft operates as a commuter over stage lengths of 200 n-miles without significant commercial freight. A shock oil price of 25% is forecast on year 2. A risk analysis is possible by using stochastic data of the parameters. Figure 1 shows a typical result.

Note that carrying extra fuel weight will cause additional emissions on the outbound flight, and this option has been publicly discouraged in the recent past.

ASSUMPTIONS ON WORK PRACTICES

- Working hours/week = 35 (flight attendants)

- Flight hours/month = 80 (pilots)

- Total pilots = 8

- Total flight assistants = 16

- Airplane utilisation = 5,232 [hours/year]

- Cycles per day = 8

- Effective cycles = 2,880 (input data superseded)

- Turn-around time = 30 [minutes]

- Off-station crew nights = 0 times/year

- Inflation = 2% applied to all items except fuel

TENTATIVE DAILY SCHEDULE

- Departure at 7:00 ; Arrival at 8:20

- Departure at 8:50 ; Arrival at 10:10

- Departure at 10:39 ; Arrival at 11:58

- Departure at 12:28 ; Arrival at 13:47

- Departure at 15:17 ; Arrival at 16:36

- Departure at 17:05 ; Arrival at 18:25

- Departure at 18:55 ; Arrival at 20:14

- Departure at 20:44 ; Arrival at 22:05 (back at origin airport)